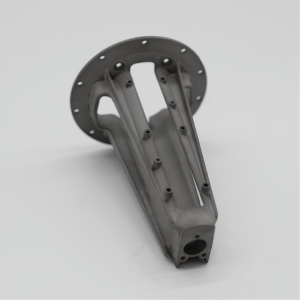

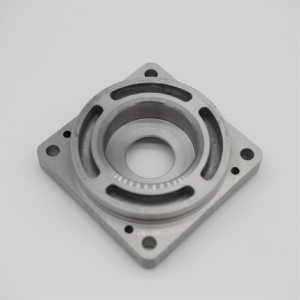

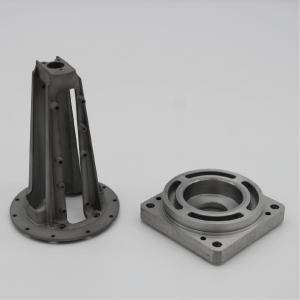

DIE CASTING

This process involves steel molds which are designed specifically for each product and molten metal is poured or forced into those molds. This process is typically used for high-volume production runs as it’s more efficient and can be used for a variety of different applications. For the past four decades, Mascon has produced the highest quality metal products for our customers. We are experienced in delivering die-cast products in a wide range of materials, including aluminum, zinc, magnesium, and lead alloys. While ensuring our services are competitively priced and only the best materials are sourced.

OUR EXTENSIVE CAPABILITY PARAMETERS ARE:

- Weight/size of part: 0.008kg – 10kg / 0.03″ to 20″

- Accuracy of +/- 0.005″ tolerance

- Thin wall: 0.025″ – 0.035″

- Expertise in complex shapes and sizes

COMPARED TO INVESTMENT CASTING

The investment casting process is generally used for more intricate designs as it has greater precision. It also uses less tooling however, the price per unit is generally higher using this process and it tends to be more time-consuming.