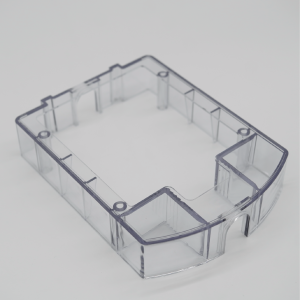

INJECTION MOLDING

Injection molding is widely used for manufacturing a variety of parts, from the smallest component to entire body panels of cars, and is one of the most common methods of production. The process involves liquified heated plastic, metal, glass or rubber that is injected into a temperature-controlled mold under high pressure. The plastic then solidifies into the mold as it cools resulting in the finished product being easily removed from the mold. Some of the major applications that use this process include:

- Medical devices

- Consumer electronics

- Automotive parts

- Packaging and beverage bottling

- Industrial components

Mascon features molding machines ranging in size from 30 to 140 tons using single and multi-cavity mold-making services.